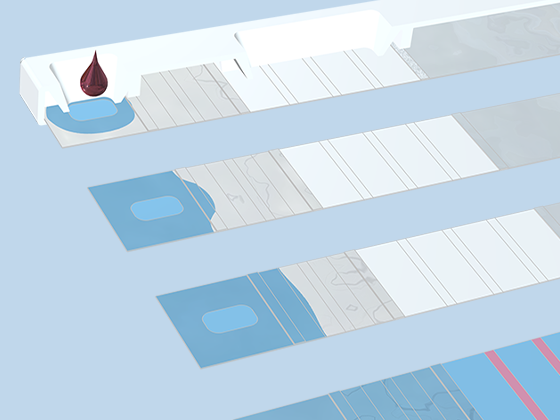

Hydrophobic meshes offer many advantages when it comes to oil spill clean-ups. “Pore Analysis” window of the Hydrophobic Mesh App. In this window one can compare both variables for a set of depths and pore radiuses. Hence, the optimum mesh size must be chosen in such a way to maximize oil flux while maintaining a low water content. Wider mesh pores enhance both water content and oil fluxes. The “Pore Analysis” window, on the other hand, can be used to determine an optimum mesh pore radius. “Breakthrough Analysis” window of the Hydrophobic Mesh App. Oil and water fluxes, oil saturation and water fractional flow can be obtained following the definition of pore radius of the mesh and operational depth interval. The “Breakthrough Analysis” window allows to determine the depth at which water breakthrough occurs. Once the parameters are introduced, analysis of the mesh can be facilitated through different studies e.g. “Set Parameters” window of the Hydrophobic Mesh App. The App allows the user to set the main parameters that define the system, such as mesh, oil and water properties, and retention function parameters. Once the Comsol model was developed, the Comsol Application Builder feature was applied to create a practical and user-friendly tool tailored for mesh designers and/or operators. App development with Comsol Application Builder Oil and water fluxes within a hydrophobic mesh as a function of mesh depth. Then the water flux increases, contaminating the recovered oil. At low depths there is only oil flowing through the mesh, with higher fluxes at higher depths, until the breakthrough pressure is reached at a depth of 0.7 m. In the Figure below, one can see the typical behavior of a hydrophobic mesh.

#Comsol 5.1 gas flow porous full

The initial condition in the mesh is full oil saturation. The water and capillary pressures were defined at the boundaries with Dirichlet boundary conditions. Implementation of the hydrophobic mesh model with the coefficient form PDE interface The model was implemented in Comsol Multiphysics using a 1D geometry and the coefficient form PDE interface. The phase mobilities depend on fluid properties and retention properties of the mesh. The porosity and permeability depend on the dimensions of the mesh, which are the coated wire radius and pore radius. is the porosity of the mesh, So the oil saturation, k the permeability of the mesh and λw and λo refer to water and oil phase mobilities, respectively.

The system of equations is solved for the water pressure, Pw, and the capillary pressure, Pc. The governing equations consist on a system of two partial differential equations, one for each phase. At the left boundary there is an oil-water mixture at hydrostatic pressure, and at the right boundary oil at atmospheric pressure. In this case there are two phases: water and oil (air was not included in the model). The model is based on the black oil model, which is extensively used for oil reservoir simulations, and solves multi-phase flow in porous media. The model presented here conceptualizes a hydrophobic mesh as a porous medium. The only disadvantage is the operation depth: when a hydrophobic mesh is submerged below its breakthrough pressure depth, water will intrude and contaminate the recovered oil.

Hydrophobic meshes are still at an early development stage but offer many advantages: they are clean, can be operated continuously, require low energy input, present good recovery capacities and recover pure oil, which allows to recycle the spilled oil. They act as a filter: the oil passes through the mesh, while water is retained outside. Hydrophobic meshes are generally made of stainless steel and coated with a hydrophobic and oleophilic material. There are several oil spill clean-up techniques, such as skimming, in-situ burning, biodegradation, hydrophobic meshes, etc. Accidental oil spills in aquatic environments are a recurring problem in the oil and gas industry and have severe ecological, social and economic consequences.

0 kommentar(er)

0 kommentar(er)